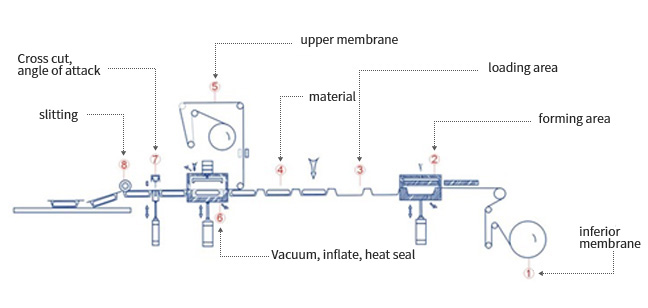

1. Equipment front end (bottom) (lower membrane frame)

Before the operation of the equipment, take a roll of lower film and install it on the lower film frame, open the lower film, and install the lower film between the chain clips.

On the roller, manually jog the switch to make the film step slowly, and stop jogging after stepping into the forming area.

2. Equipment front end (upper) (molding area)

It consists of a forming die and an upper heating die to form the lower film into a set shape.

3. In the middle of the equipment (unloading area), the packaging materials need to be put into the loading area. The automatic feeding device can be set up according to the regular materials to save labor as much as possible. After the crayfish materials are visited neatly, we add a fully automatic filling system to fill soup and oil respectively to ensure that the error of soup and oil is 500 grams plus or minus 2% .

4. The middle of the equipment (sealing and vacuum area)

It is composed of a sealing mold and an upper heating mold. The equipment reaches the sealing vacuum area by stepping, and the lower film mold passes through the upper part of the cylinder.

Lift and press the upper heating mold, and then vacuumize through the vacuum pipeline, and finally complete the sealing.

5. Equipment tail (punching part)

Recycling and cutting use flywheels on the left and right, and cylinder + blade for cross-cutting, without punching.

6. The tail of the equipment (waste recycling rack) is used for recycling waste after punching.

7. The upper end of the equipment (control panel and upper film frame)

The whole machine is operated by PLC control panel to set specific parameters and stop running.

Upper film holder: Take a roll of upper film and install it on the upper film holder, and put the upper film into the sealing area through the sliding rod.