Tel:+86-13353371368(Mr.Tan)

Video

Overview

Process

Parameter

1. Based on the improvement of the BD-8ZK10-130 model, the production capacity of one machine can now reach the efficiency of the original two machines, and the packaging speed is 120 packs per minute, which effectively improves space utilization and production capacity.

2. The fully automatic bag-feeding vacuum packaging machine produced by our company has reasonable design, beautiful appearance, high effnciency, energy saving and environmental protection. Its core power CAM adopts Japan imported materials, through 21 processing procedures, the surface wear resistance, with elasticity. The CAM is easy to maintain and clean, with a service life of up to 50 years.

3. All parts and components of the equipment conform to the relevant national standards and are mainly equipped with imported electrical components. All parts and components that come into contact with food or packaging are made of food-grade 304 stainless steel and other materials that meet the requirements of food hygiene to ensure food hygiene and safety.

4. The equipment is easy to operate and adopts advanced mechanical transmission system to realize automatic bag taking, automatic weighing, automatic loading, automatic vacuum pumping, automatic sealing and automatic unloading. .

5. The vacuum air closure device of the equipment is made of synthetic materials jointly developed by our company and Germany, which can realize zero friction and zero wear in the vacuum packaging process and provide a lifetime quality guarantee.

6. The equipment has its own lubrication system and lubricating oil tank. The system can recycle and filter the excess oil, realize recycling and extend the service life of the equipment.

|

Device length and width |

Length: 3000mm Width: 1900mm |

|

bag type |

Various film bags such as aluminum foil bags, paper bags, nylon bags, etc. |

|

bag size |

Length: 60-150mm Width: 55-100mm |

|

Filling range |

10-1500g |

|

packing speed |

100-120 packs/min (the speed is determined by the product itself and the filling weight) |

|

Packaging accuracy |

Average precision≤+1% |

|

total power |

10Kw |

|

Scope of application |

Mustard shreds, mustard slices, sour beans, soy products, pickled vegetables, enoki mushrooms,kelp shreds, etc., are measured and weighed. Scattered dried tofu, pickled vegetables, duck tongue, dried egg, dried tea, large pieces of dried tofu, chicken popcorn, spicy chicken nuggets, chicken joints, chicken thighs, chicken necks, chicken feet, duck gizzards, duck feet, duck legs, wing roots , wing tips, marinated eggs, middle wings, two-section wings, three-section wings and other irregular materials

|

|

Optional package |

Material weighing and filling machine, working platform, weight sorting scale, material hoist, finished product conveying hoist, metal detector |

|

Measurement method |

Multi-head computer combination scale, screw scale, filling machine, shrink cup |

|

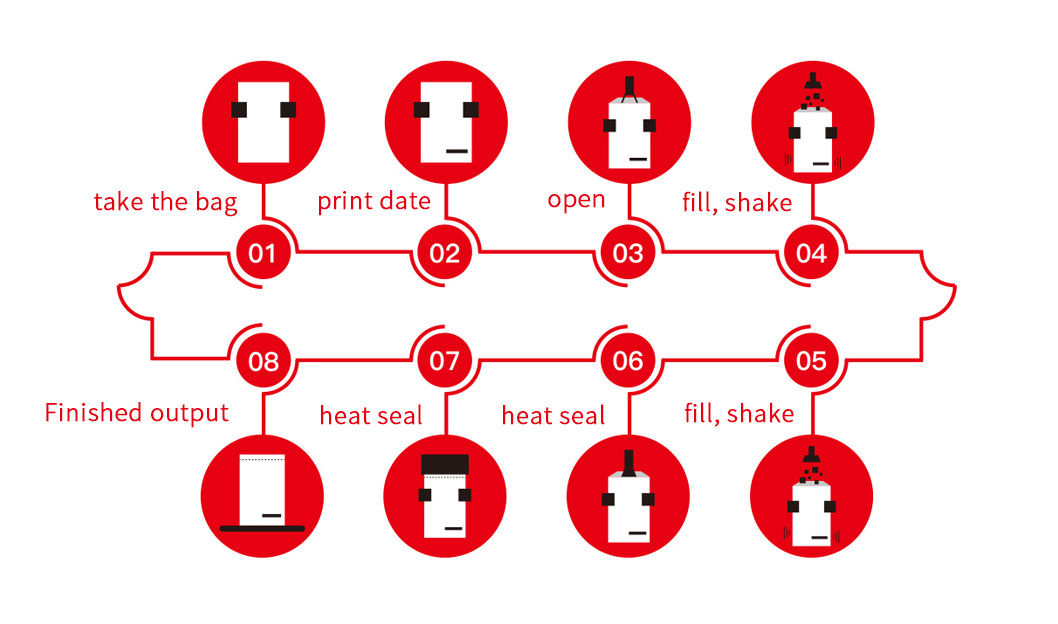

work process |

Loading the bag→printing the production date→opening the bag→cutting 1→cutting 2→reservation→heat sealing→shaping and output |

+86-13353371368(Mr. Tan)

+86-0577-65026568

+86-0577-65708680

1585978132@qq.com

No. 281 Wanxiang Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, Bedde machinery Factory two

Scan WeChat