Tel:+86-13353371368(Mr.Tan)

Video

Overview

Features

Process

Parameter

Adopt Japanese Mitsubishi programmable controller control, color touch screen, choose Mitsubishi frequency conversion speed, full The department uses electrical appliances from Japan, Europe, and Taiwan. With complete security protecon measures.

The equipment consists of double my company independent research and development of continuous stretching vacuum packaging machine, also called double aluminum film vacuum packaging machine. Double stretch wrapping machine makes up only the blank side stretch wrapping machine,satisfy the need of aluminum foil packaging products demand.

Suitable for all kinds of leisure food: fish, tofu, fish, beef, duck tongue, great products and so on , these could be vacuum packaging by this machine.

|

|

|

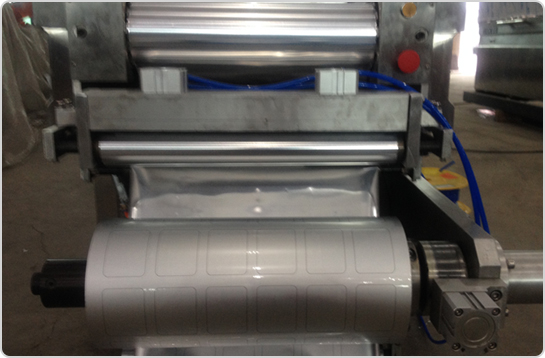

1、Front end of equipment (bottom) (lower membrane holder) Before the equipment is operated, it is necessary to take a roll of the lower film and install it on the lower film frame, open the lower film, install the lower film on the roller between the chain clips, and manually move the switch to make the film slowly step to the forming area. Then stop jogging. |

2、Front end of equipment (upper) (forming area) It consists of a forming die and an upper heating die to form the lower film into a set shape. |

|

|

|

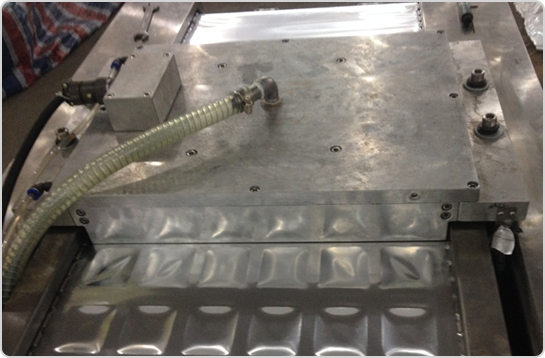

3、The middle of the equipment (the upper film thermoforming area) Just place the materials in the formed grid, and leave the rest to the machine. |

3、The middle of the equipment (the upper film thermoforming area) Upper film forming and film forming tool (the self-developed upper forming device, at present, many companies can only do single-sided stretching packaging machines.) |

|

|

|

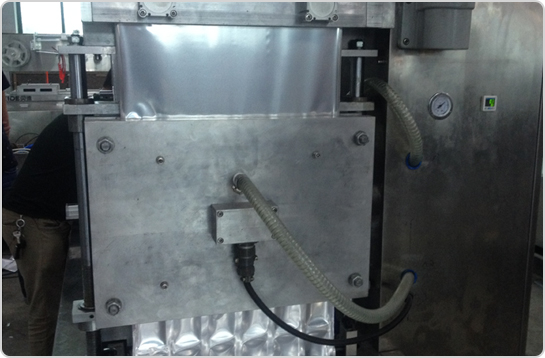

4、Middle of the device (sealing and vacuum area) From the sealing mold and the upper heating mold, the equipment reaches the sealing vacuum area by stepping, the lower film mold rises through the cylinder, presses the upper heating mold, and then vacuumizes through the vacuum pipeline, and finally completes the sealing. |

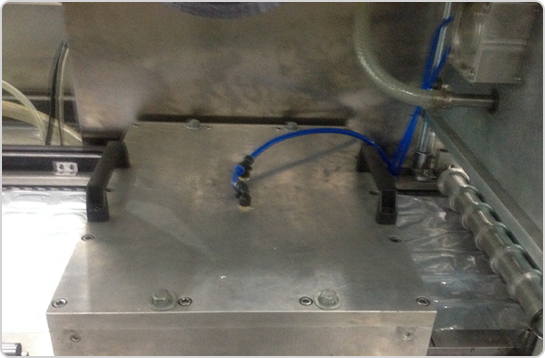

5、Equipment tail (waste recycling rack) The flywheel is used for recycling and cutting, and the cylinder + blade is used for cross-cutting, without flushing. |

|

|

|

6、Equipment tail (waste recycling rack) Scrap recycling after punching |

7、The upper end of the equipment (control panel and upper film frame)

The whole machine is operated by PLC control panel to set specific parameters and stop running. Upper film holder: Take a roll of upper film and install it on the upper film holder, and put the upper film into the sealing area through the sliding rod.

|

Film width(upper) |

495(395)mm |

|

Film width(under) |

523(423)mm |

|

Working room size |

400×(300-400)mm |

|

Air consumption |

≥0.6MPa 0.3m³ |

|

Vacuum |

-0.10MPa |

|

Voltage |

380V 50HZ |

|

Total power |

13kw |

|

Dimension |

6500×1170(1070)×1700mm |

|

The largest tensile strength |

20mm |

|

Weight |

2200kg |

Notes:If any change of data,we will not notify further.

+86-13353371368(Mr. Tan)

+86-0577-65026568

+86-0577-65708680

1585978132@qq.com

No. 281 Wanxiang Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, Bedde machinery Factory two

Scan WeChat